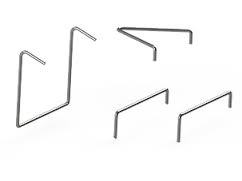

Refractory U Shapes Anchor

Refractory U Shapes Anchor Specification

- Weight

- Varies as per Size

- Capacity

- Heavy Duty

- Surface Treatment

- Galvanized / Heat Treated

- Finishing

- Smooth

- Material

- Stainless Steel

- Type

- U Shape Anchor

- Length

- 100 mm - 300 mm

- Diameter

- 5 mm - 16 mm

- Surface

- Polished

- Grade

- 304, 316, 310, Mild Steel

About Refractory U Shapes Anchor

Refractory U Shapes Anchor

Refractory U Shapes Anchor manufactured and supplied by our company is fabricated by using best in class alloyed steel that provides high tensile and compressive strength. It is commonly used in industrial furnaces to clamp brick lining materials and various castables. The offered fitting element is made up by using latest production methods that lead to high dimensional accuracy. Refractory U Shapes Anchor offered by our company is also provided with galvanized coat that helps in the prevention of damages due to rust. The compact design, high load bearing capacity, and good thermal resistance makes it highly demanding among our customers.

Robust Solution for High-Temperature Environments

Our Refractory U Shape Anchors are specially designed for demanding thermal settings, including furnaces, kilns, and ovens. They offer high mechanical strength, excellent corrosion resistance, and adaptability to different refractory designs. Crafted from superior materials, these anchors help maintain the integrity of refractory linings under thermal stress.

Customizable Anchoring for Industrial Applications

We offer tailored options to fit unique engineering needs. From size and grade to surface treatment and packaging, every anchor can be produced according to your projects specifications. Whether you require heat-treated, galvanized, or specialized finishes, our team ensures each product meets precise operational demands.

FAQs of Refractory U Shapes Anchor:

Q: How do you install a Refractory U Shape Anchor in high-temperature settings?

A: Installation typically involves either welding the U Shape Anchor directly onto the furnace, kiln, or oven wall, or mechanically fastening it with bolts. The chosen method depends on the structural requirements and accessibility of the application.Q: What are the main benefits of using these anchors for refractory material fixation?

A: The primary benefits include high temperature resistance (up to 1600C), robust mechanical strength, and outstanding corrosion resistance. Their U-shaped configuration provides enhanced stability, preventing displacement of refractory materials during thermal expansion and contraction.Q: When should I choose stainless steel versus mild steel for U Shape Anchors?

A: Stainless steel grades (304, 316, 310) are recommended for applications demanding superior corrosion and heat resistance, while mild steel may suffice for less extreme environments. Selection depends on specific operating temperatures and chemical exposure.Q: Where are Refractory U Shape Anchors typically used?

A: These anchors are widely utilized in lining fixations for industrial furnaces, rotary kilns, baking ovens, and other equipment where high temperature resistance is critical for product longevity and operational efficiency.Q: What is the process for customizing anchors as per specific project requirements?

A: Customization involves submitting your drawing or technical specifications, based on which our team will manufacture the U Shape Anchors to your required dimensions, material grade, and finishing preferences. We also accommodate special packaging and order quantity requests.Q: How do I determine the correct anchor size and grade for my application?

A: Selecting the appropriate size (length and diameter) and grade depends on factors such as the refractory thickness, thermal load, and environmental conditions. Our technical team is available to assist in evaluating your requirements and recommending the best fit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory U Anchors Category

Refractory U Anchors

Surface Treatment : Other , Galvanized / Polished / Coated

Weight : As per size and specification

Grade : SS 304, SS 310, SS 316, MS, Alloy

Length : 75 mm to 300 mm

Type : Other, U Type Refractory Anchor

Surface : Polished / Plain

REFRACTORY U SHAPE ANCHORS

Surface Treatment : Other , Pickled / Polished / Zinc Coated

Weight : Varies as per size and specification

Grade : SS 304, SS 310, MS

Length : 65 mm to 300 mm (customization available)

Type : Other, U Shape Anchor

Surface : Plain / Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS