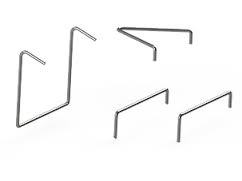

Refractory U Anchors

Refractory U Anchors Specification

- Weight

- As per size and specification

- Surface Treatment

- Galvanized / Polished / Coated

- Capacity

- High temperature load-bearing

- Finishing

- Bright / Matte

- Material

- Stainless Steel / Mild Steel / Alloy Steel

- Type

- U Type Refractory Anchor

- Length

- 75 mm to 300 mm

- Diameter

- 5 mm to 12 mm

- Surface

- Polished / Plain

- Grade

- SS 304, SS 310, SS 316, MS, Alloy

- Customization

- Available as per drawing or specification

- Standard

- IS/ASTM/DIN (Customized as per order)

- Corrosion Resistance

- High, with special grades for oxidizing environments

- Edge Type

- Chamfered / Plain

- Tensile Strength

- Up to 500 MPa (Depending on Grade)

- Application

- Fixation of refractory linings in kilns, furnaces, and boilers

- Packaging

- Carton / Gunny Bags / Wooden Box

- Weldability

- Excellent (for stainless steel and alloy grades)

- Temperature Resistance

- Up to 1600°C (Depending on Material and Grade)

About Refractory U Anchors

This precisely developed Refractory U Anchor is made of 253MA stainless steel. This concrete anchor has exceptional strength and it has been developed as per ANSI or CE specifications. Its color is nickel white and it has fine threading that conforms to global norms. Provided Refractory U Anchor has been checked on the basis of its design, strength, maneuverability, service life, surface finish, threading standard etc. This anchor has been developed by using quality certified raw materials to maintain its standard.

Superior Strength and Durability

Engineered for rigorous industrial environments, our Refractory U Anchors offer outstanding tensile strength and high load-bearing capacity. Manufactured from premium-grade stainless steel, mild steel, or alloy steel, they are designed to reliably secure refractory linings, ensuring operational stability and safety even in high-temperature applications.

Adaptable to Your Needs

Available in various grades such as SS 304, SS 310, and SS 316, and in customizable sizes, our anchors are suitable for diverse refractory applications. Whether you require specific lengths, diameters, or edge finishes, customization based on drawings or specifications guarantees optimal performance for every installation.

Corrosion and Temperature Resistance

Our U Anchors are specially crafted to resist corrosionincluding challenges posed by oxidizing environmentsand withstand temperatures up to 1600C, making them an ideal solution for kilns, furnaces, and boilers. Optional surface treatments like galvanizing, polishing, and coating further extend anchor longevity in harsh conditions.

FAQs of Refractory U Anchors:

Q: How are refractory U anchors installed in kilns and furnaces?

A: Refractory U anchors are typically welded onto the steel shell or backing of kilns, furnaces, or boilers. Their excellent weldability, especially in stainless steel and alloy grades, ensures a secure and reliable fixation, holding the refractory lining firmly in place during thermal cycling and operation.Q: What materials and grades are available for refractory U anchors?

A: These anchors are available in stainless steel grades such as SS 304, SS 310, SS 316, as well as mild steel and customized alloys. Selection depends on the operating temperature, environment, and specific requirements for corrosion and load resistance.Q: When should I choose a special grade for corrosive or oxidizing environments?

A: Special grades or alloys should be selected when operating in highly corrosive or oxidizing environments. These materials offer enhanced resistance, protecting the anchor and lining from premature degradation and ensuring longer service life.Q: Where are U-type refractory anchors most commonly used?

A: U-type refractory anchors are extensively used in industrial kilns, furnaces, boilers, incinerators, and other high-temperature processing equipment where secure fixation of refractory linings is essential for safe and efficient operation.Q: What are the size and customization options for these anchors?

A: Refractory U anchors can be supplied in lengths from 75 mm to 300 mm and diameters from 5 mm to 12 mm. Edge types can be chamfered or plain, and surface finishes include polished, matte, or coated. Customization is available to match your specific drawings or operational requirements.Q: How does the surface treatment benefit the product?

A: Surface treatments such as galvanizing, polishing, or coating enhance corrosion resistance and prolong the anchors lifespan by protecting against harsh environmental factors including moisture, chemicals, and heat.Q: What are the key benefits of using these anchors in refractory lining installation?

A: Using refractory U anchors ensures stable and durable fixation of linings, superior high-temperature performance, resistance to corrosion, and adaptability for various installation requirements. This contributes to longer equipment lifespan and reduced maintenance downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refractory U Anchors Category

Refractory U Shapes Anchor

Finishing : Other, Smooth

Surface Treatment : Other , Galvanized / Heat Treated

Material : Other, Stainless Steel

Diameter : 5 mm 16 mm

Type : Other, U Shape Anchor

Capacity : Heavy Duty

REFRACTORY U SHAPE ANCHORS

Finishing : Other, Smooth / Uncoated / Polished

Surface Treatment : Other , Pickled / Polished / Zinc Coated

Material : Other, Stainless Steel / Mild Steel

Diameter : 3 mm to 16 mm

Type : Other, U Shape Anchor

Capacity : Suitable for holding refractory lining in furnaces at elevated temperatures

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS