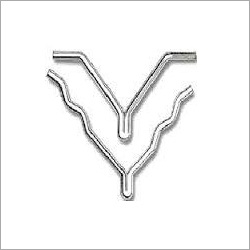

Refractory Stud Anchors

Refractory Stud Anchors Specification

- Surface Treatment

- Galvanized / Polished / Passivated

- Capacity

- Standard and Heavy Duty

- Finishing

- Smooth / Bright / Coated

- Weight

- As per Size & Specification

- Material

- Mild Steel / Stainless Steel / Alloy Steel

- Type

- Refractory Stud Anchor

- Length

- 50 mm to 300 mm (custom sizes available)

- Diameter

- 6 mm to 16 mm

- Surface

- Bright / Hot Dip Galvanized / Zinc Plated

- Grade

- SS 304, SS 310, SS 316, EN8, EN24, ASTM & Other Grades

About Refractory Stud Anchors

With strong commitment to quality, we are instrumental in offering an excellent collection of Refractory Stud Anchors. Ideally used in various industrial fittings, these anchors are known for their high tolerance. Offered anchors are manufactured with efficiency by our experienced professionals with the use of sophisticated methods. Also, the provided Refractory Stud Anchors are made available to the customers in bulk and varied dimensions.

Features:

- Rugged design

- Excellent finish

- High tensile strength

- Abrasion resistance

Versatile Applications in Industrial Settings

Refractory Stud Anchors are indispensable in industries such as steel, cement, petrochemical, and power generation, where they anchor refractory linings to furnace shells, kilns, and boiler structures. Their compatibility with monolithic refractories, ceramic linings, and castable systems makes them a trusted component for maintaining structural integrity under intense thermal and mechanical stress.

Wide Range of Material and Finish Options

These stud anchors are available in diverse materialsincluding mild steel, alloy steel, and stainless steel grades such as SS 304, SS 310, and SS 316and feature various surface treatments like bright finish, hot dip galvanizing, zinc plating, polishing, and passivation. Clients can select the most suitable combination for their operational environment, ensuring optimal corrosion resistance and performance.

Customizable Solutions for Specific Needs

Manufacturers provide full customization, building refractory stud anchors to client drawings and specifications. Shapes, sizes, and finishes can all be tailored, while packaging options range from standard boxing to custom bundles. This adaptability guarantees perfect fitment and efficient, reliable installation for any refractory anchoring project.

FAQs of Refractory Stud Anchors:

Q: How are refractory stud anchors installed in industrial applications?

A: Refractory stud anchors are typically installed by direct welding, stud welding, or threading them onto steel structures or vessel surfaces. This provides a secure and durable attachment, ensuring the refractory lining or castables remain firmly in place under high thermal and mechanical loads.Q: What material options are available for refractory stud anchors?

A: These anchors are manufactured from a range of materials, including mild steel, various alloy steels, and corrosion-resistant stainless steel grades such as SS 304, SS 310, and SS 316. Selection depends on the specific temperature, chemical environment, and mechanical requirements of your project.Q: When should I use custom refractory stud anchors instead of standard sizes?

A: Custom refractory stud anchors are ideal when your application demands unique dimensions, shapes, or surface treatments that differ from industry standard offerings. Customization ensures the anchors precisely fit project parameters, enhancing installation efficiency and overall system stability.Q: Where are refractory stud anchors commonly utilized?

A: These anchors are commonly utilized in furnaces, boilers, kilns, and similar high-temperature structures across industries such as steelmaking, cement production, petrochemical refining, and power generation, where they secure refractory linings to metal shells.Q: What are the benefits of using stainless steel refractory stud anchors?

A: Stainless steel refractory stud anchors provide excellent corrosion resistance, especially in aggressive chemical or moisture-rich environments, and can withstand operating temperatures up to 1350C, making them suitable for heavy-duty, high-temperature industrial applications.Q: What shapes and sizes do refractory stud anchors come in?

A: Available shapes include V-shaped, Y-shaped, U-shaped, and Crook anchors, with diameters ranging from 6 mm to 16 mm and lengths from 50 mm to 300 mm. Custom sizes and drawings can also be accommodated as per client requirements.Q: How do I select the appropriate surface treatment for my refractory stud anchors?

A: The choice of surface treatmentsuch as bright finish, hot dip galvanized, zinc plated, or passivateddepends on your applications exposure to corrosive elements and temperature. Selecting the right treatment enhances durability and extends the operational lifespan of the anchors.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refractory Stud Anchors Category

Refractory Stud Anchor

Diameter : 6 mm

Material : Other, Stainless Steel

Weight : Approx. 2050 Grams

Capacity : High Temperature Resistant

Grade : 304/316

Type : Other, Y Type Refractory Stud Anchor

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS